Innovative Manufacturing Techniques: In-Mold Decorations Explained

Innovative Manufacturing Techniques: In-Mold Decorations Explained

Blog Article

Understanding In-Mold Decorations: Strategies, Fads, and Ideal Practices for Optimum Results

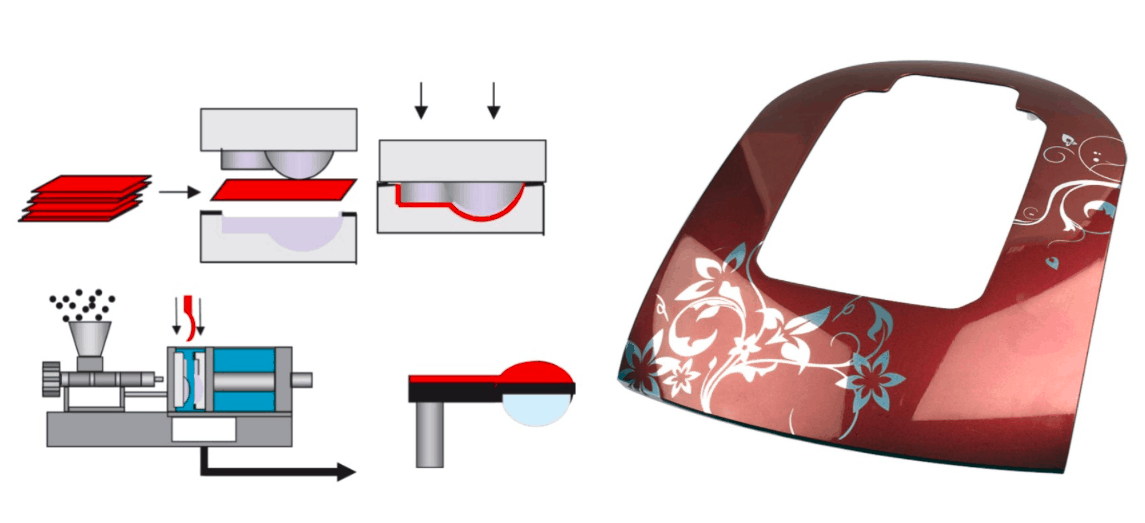

In the world of manufacturing, the art of in-mold decors stands as a critical facet of item style and production. As markets continually seek cutting-edge ways to improve aesthetic appeal and performance, grasping the intricacies of in-mold decors has arised as a vital capability. From choosing the appropriate products to integrating sophisticated design patterns, the trip in the direction of achieving optimum cause this domain is diverse. By diving into the techniques, patterns, and finest methods that underpin effective in-mold decoration procedures, services can open a realm of possibilities that not just boost the visual allure of their items however also enhance manufacturing efficiency and bolster consumer interaction.

Product Choice

Material choice is a vital aspect of grasping in-mold designs, as it directly impacts the quality and resilience of the last item. When choosing materials for in-mold designs, it is vital to take into consideration factors such as compatibility with the molding procedure, the wanted aesthetic end result, and the ecological problems the product will encounter. Polycarbonate products like polypropylene, polycarbonate, and abdominal are commonly utilized for in-mold designs as a result of their adaptability and capacity to accomplish elaborate designs. These materials offer excellent moldability, allowing manufacturers to develop complicated shapes and patterns with accuracy.

In addition, the chosen product must have great attachment properties to guarantee that the decor adheres securely to the substrate during the molding procedure. Attachment between the material and the decor is crucial for protecting against delamination and ensuring resilient aesthetic appeal. Additionally, materials with high warm resistance are favored for in-mold decorations, particularly for items that will certainly be subjected to raised temperatures during their lifecycle. By very carefully picking the ideal product for in-mold designs, suppliers can enhance the overall quality and sturdiness of their items, satisfying the expectations of both clients and end-users.

Layout Technology

A necessary element in progressing the area of in-mold decorations is the continual expedition and application of layout innovation methods. Style innovation plays a vital duty in boosting the aesthetic appeal, capability, and total quality of items produced utilizing in-mold design procedures. By including innovative design elements, producers can differentiate their products in the marketplace, bring in customers, and remain in advance of competitors.

One of the key elements of design technology in in-mold designs is the assimilation of elaborate patterns, textures, and graphics that were formerly testing to attain with standard decor methods. Advanced innovations such as 3D printing and electronic design tools allow developers to produce facility and thorough layouts that can be seamlessly moved onto shaped parts. Furthermore, making use of lively colors, metallic finishes, and unique results like gloss or matte appearances can better boost the visual charm of in-mold decorated products.

Additionally, style advancement expands beyond visual appeals to include practical enhancements such as ergonomic shapes, integrated functions, and adjustable elements that accommodate certain customer needs. By embracing design development, suppliers can open brand-new possibilities for personalization, item, and creative thinking distinction in the affordable landscape of in-mold designs.

Manufacturing Efficiency

Effective manufacturing procedures are vital for converting the cutting-edge styles established in the area of in-mold designs right into top notch completed items that meet market demands and customer expectations. In the realm of in-mold decorations, production effectiveness includes numerous vital elements that contribute to the overall success of the production procedure.

Furthermore, carrying out automation and robotics in the assembly line can considerably boost performance by improving repeated jobs and lowering the margin of mistake. Automation not only increases the manufacturing process but also boosts accuracy and repeatability, causing a much more top quality and uniform end item. Embracing lean manufacturing principles, such as just-in-time inventory monitoring and waste decrease strategies, can further enhance manufacturing efficiency by lessening downtime and enhancing source usage. Overall, a holistic approach to production efficiency is vital in maximizing the possibility of in-mold decor methods and accomplishing optimal results in the affordable market landscape.

Quality Assurance Actions

What are the vital methods for guaranteeing rigorous quality assurance steps in the realm of in-mold designs? Quality assurance actions are paramount in in-mold design procedures to ensure the production of perfect and top quality completed products. One essential approach is the execution of strenuous examination methods at every phase of the production procedure. This entails performing complete aesthetic assessments, dimensional checks, and shade consistency assessments to identify any flaws or variances at an early stage.

Making use of sophisticated innovations such as automated examination systems can also improve the quality control procedure by offering accurate and reliable data for analysis. These systems can discover imperfections that may be missed by manual evaluations, therefore enhancing total item top quality and uniformity.

Normal training and advancement programs for employees included in the in-mold design process can also add see this website to maintaining high-grade criteria. By informing personnel on finest techniques, top quality expectations, and the value of attention to information, business can foster a culture of quality awareness throughout the organization.

Customer Appeal

To boost the marketability of in-mold design products, comprehending and providing to customer choices play a crucial function in identifying their charm and success. Using customization alternatives such as personalized styles, shade variations, and textural components can significantly improve the allure of in-mold decoration products.

Final Thought

In-mold designs supply a reliable and versatile means to improve item aesthetic appeals. Grasping in-mold designs calls for an all natural strategy that takes into consideration all elements of the manufacturing procedure to make certain success.

In the world of manufacturing, the art of in-mold decors stands as a crucial aspect of product style and manufacturing. Style development plays a vital function in enhancing the aesthetic charm, capability, and total high quality YOURURL.com of products produced utilizing in-mold design procedures.One of the vital aspects of layout advancement in in-mold designs is the combination of complex patterns, appearances, and graphics that were formerly challenging to attain with conventional decor methods.Reliable production processes are essential for translating the cutting-edge layouts created in the field of in-mold decorations right into high-grade completed products that fulfill market demands and customer assumptions. Providing modification alternatives such as customized styles, shade variations, and textural components can dramatically improve the Get More Information charm of in-mold decoration items.

Report this page